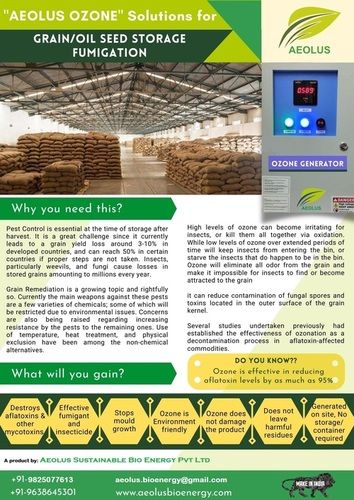

Grain and Oil Seed Storage Fumigation with Ozone by Aeolus

Product Details:

- Product Type Advance Oxidation & disinfection system based on Ozone

- Material Ozone Generator with corona discharge technology

- Voltage 220-240 Volt (v)

- Frequency (MHz) 50 Hertz (HZ)

- Warranty 1 year conditional

- Click to View more

Grain and Oil Seed Storage Fumigation with Ozone by Aeolus Price And Quantity

- 1 Plant

Grain and Oil Seed Storage Fumigation with Ozone by Aeolus Product Specifications

- Advance Oxidation & disinfection system based on Ozone

- 50 Hertz (HZ)

- 1 year conditional

- 220-240 Volt (v)

- Ozone Generator with corona discharge technology

Grain and Oil Seed Storage Fumigation with Ozone by Aeolus Trade Information

- Surat

- 10 Plant Per Month

- 4 Week

- Yes

- Contact us for information regarding our sample policy

- Asia Eastern Europe Africa Australia Central America North America South America Western Europe Middle East

- Sikkim Tripura Uttarakhand Daman and Diu Dadra and Nagar Haveli South India Central India North India East India West India Andaman and Nicobar Islands Andhra Pradesh Assam Arunachal Pradesh Bihar Chhattisgarh Chandigarh Delhi Gujarat Goa Haryana Himachal Pradesh Jammu and Kashmir Jharkhand Karnataka Kerala Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Nagaland Odisha Punjab Pondicherry Rajasthan Telangana Uttar Pradesh West Bengal Lakshadweep Tamil Nadu All India

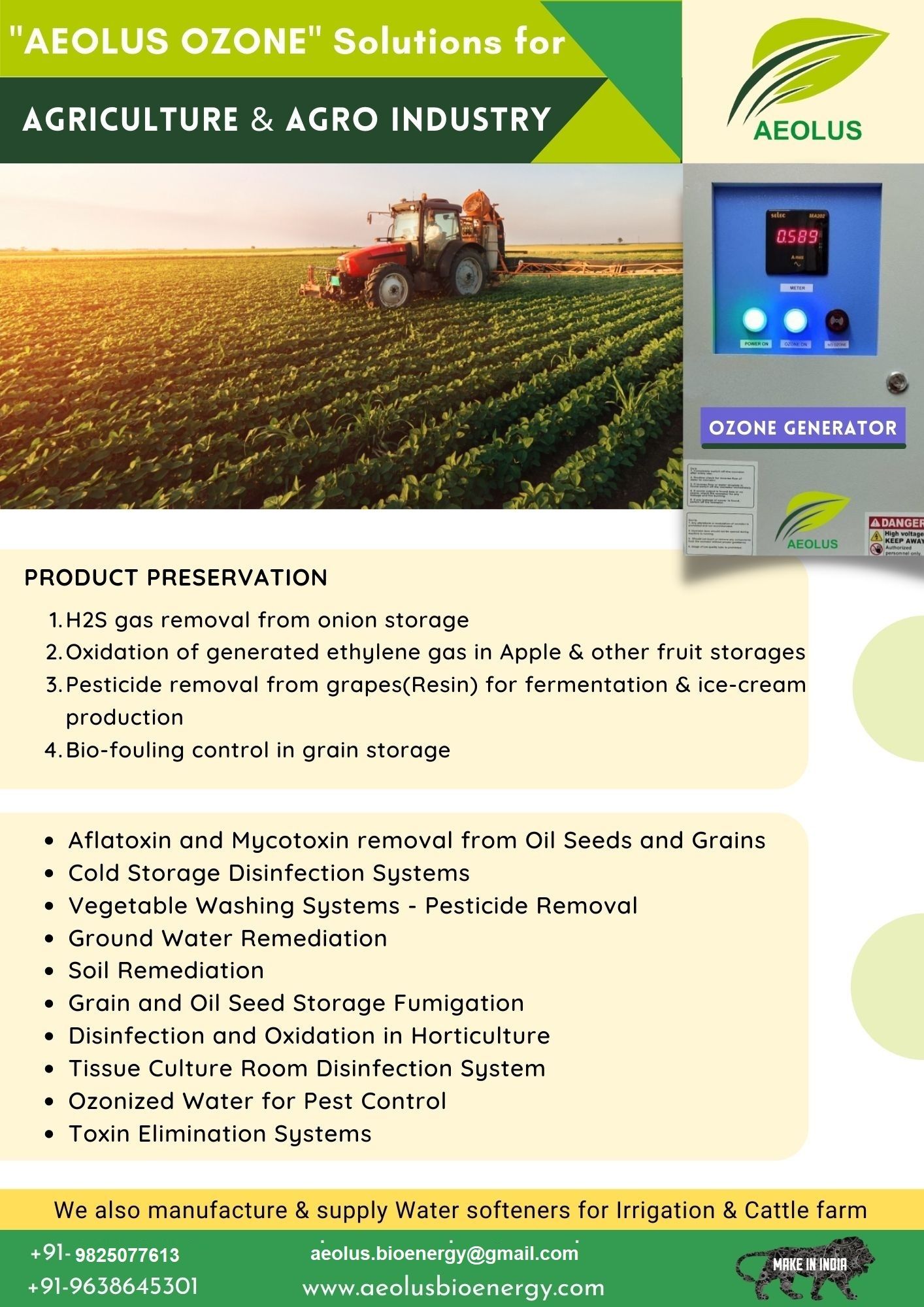

Product Description

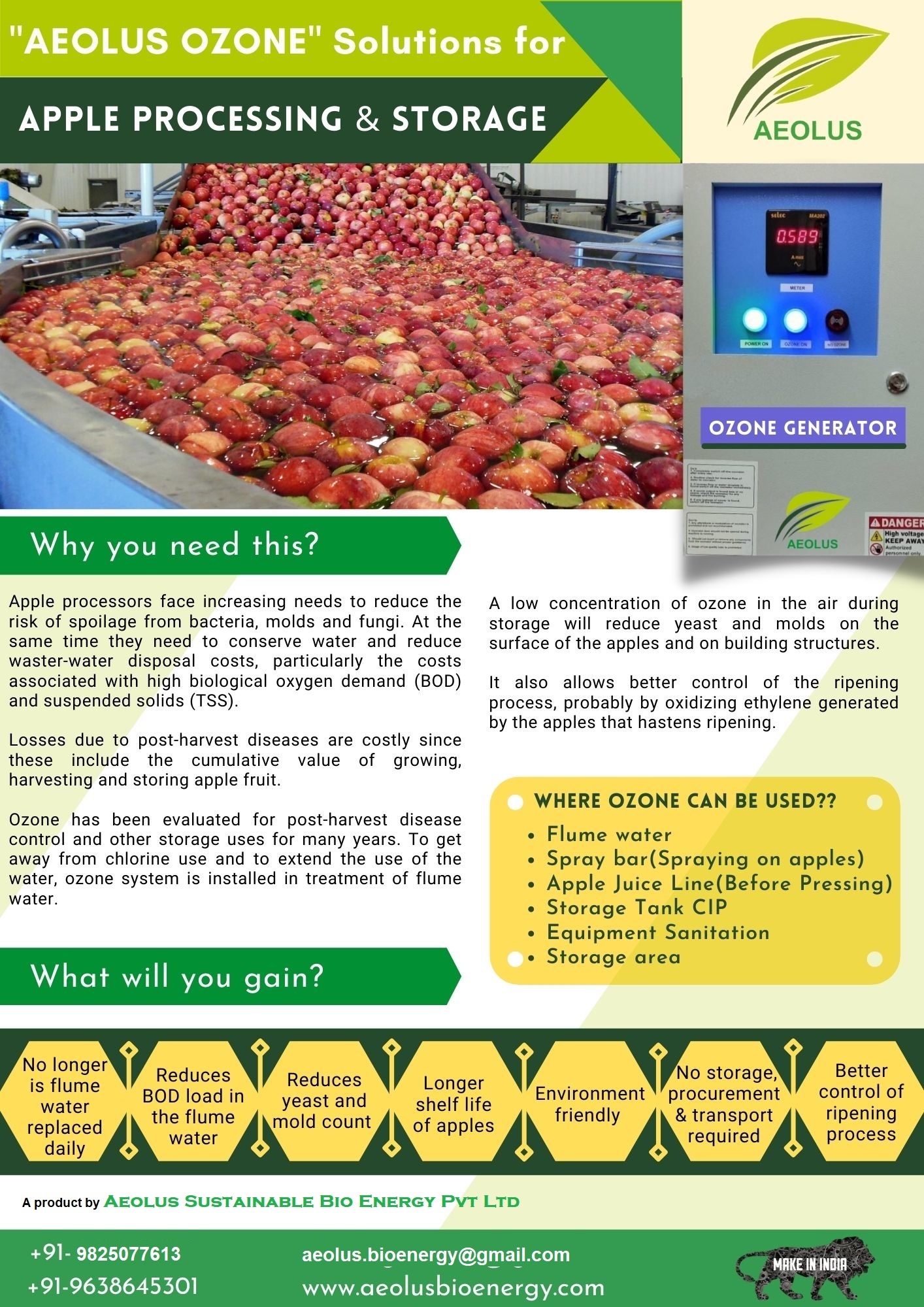

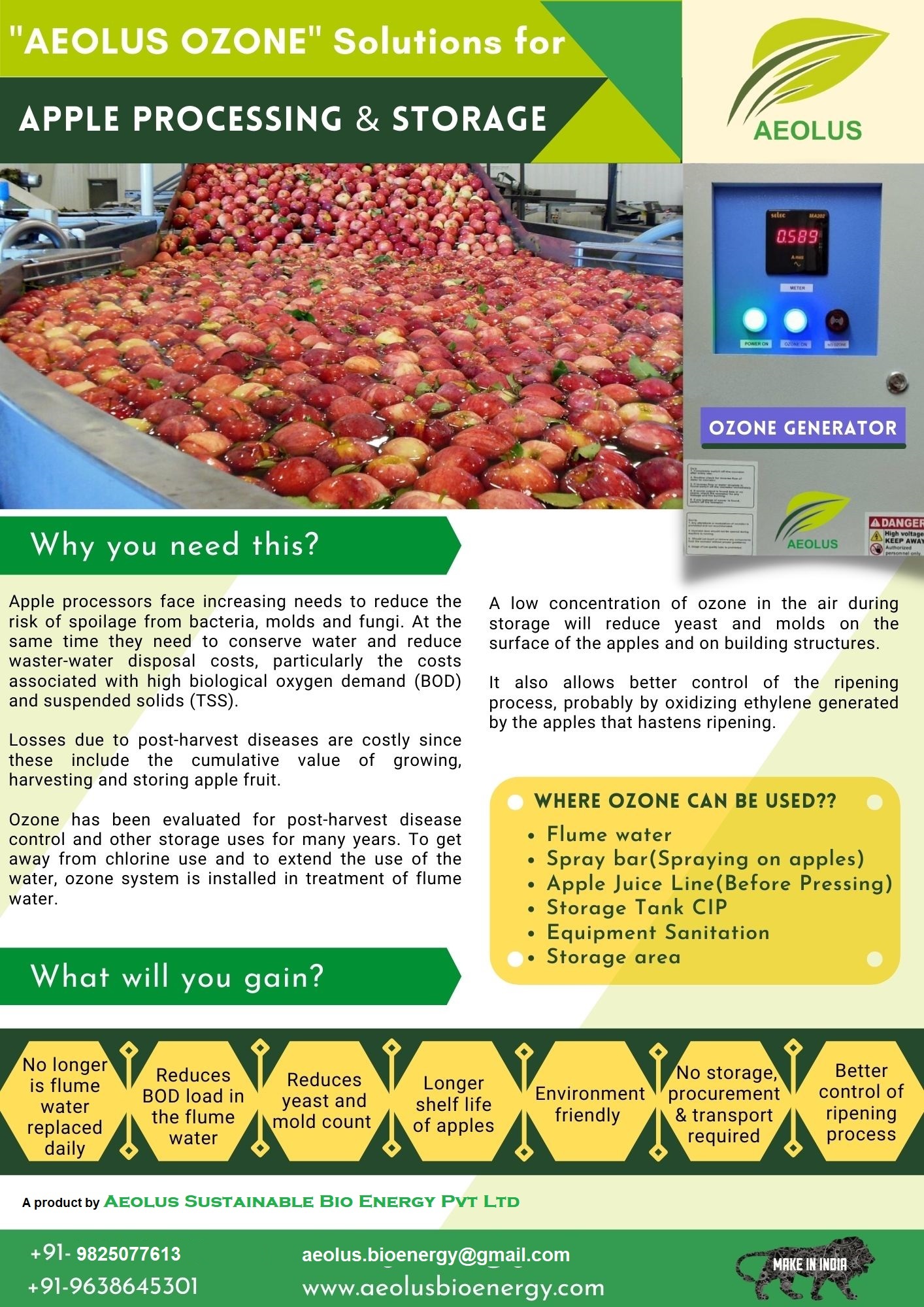

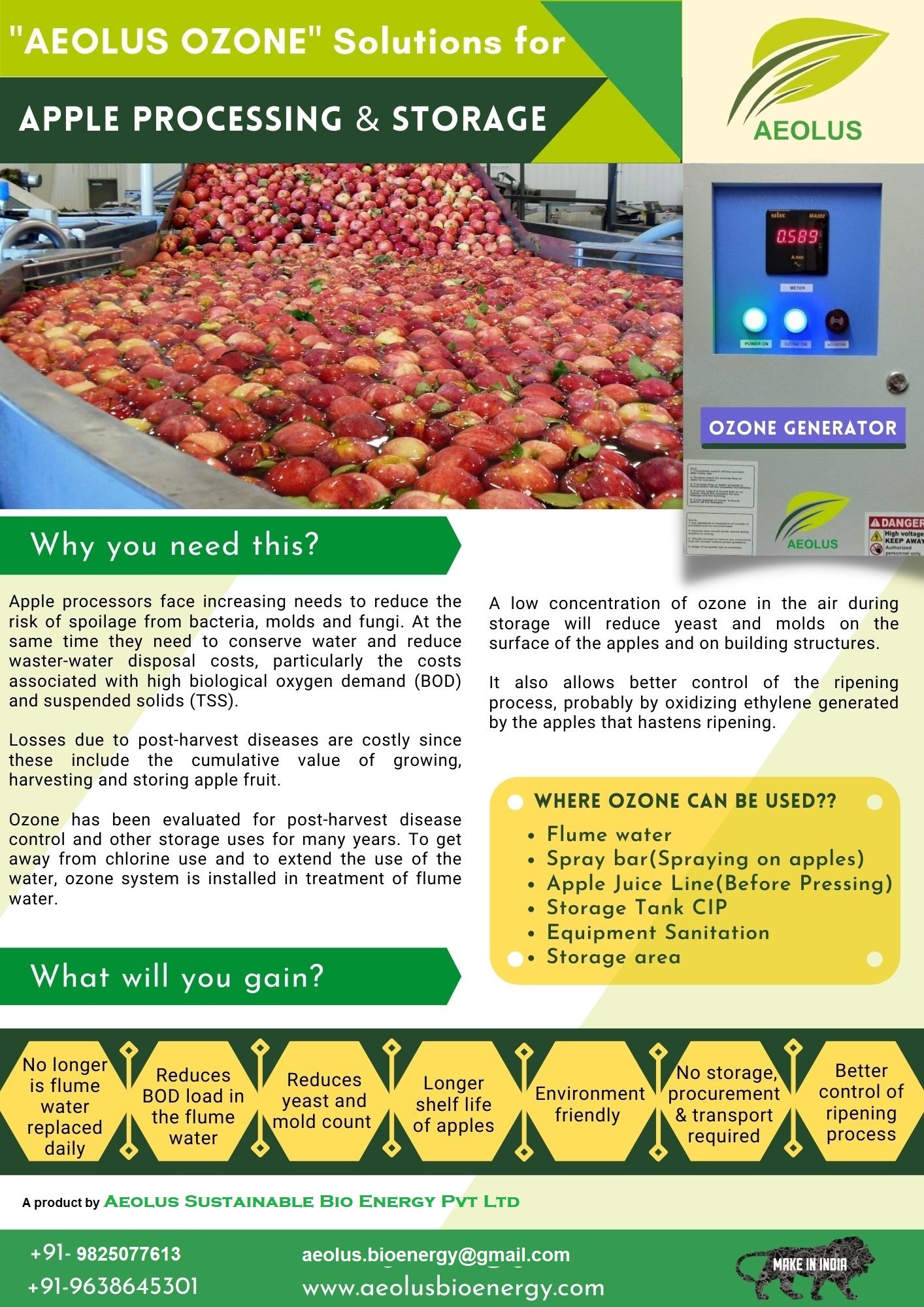

Understanding the Challenges Grain and Oilseed Storage Woes Storage of grains and oilseeds is fraught with risks such as pest infestations mold development mycotoxin contamination and overall quality degradation Traditional fumigation methods often involve chemical pesticides that raise health and environmental concerns

The Aeolus Ozone Advantage Ozone O3 a powerful and natural oxidizing agent offers a multifaceted approach to resolving storage challenges and enhancing the quality of stored grains and oilseeds

1 Pest Control

Ozone effectively eliminates pests insects and their larvae during fumigation ensuring grains and oilseeds remain free from contamination

2 Mold and Fungus Prevention

Ozone hinders mold and fungal growth which can lead to spoilage and mycotoxin development

3 Mycotoxin Reduction

Ozone exposure can lead to the breakdown of mycotoxins safeguarding the quality and safety of stored products

4 Extended Shelf Life

Ozone treatment extends the shelf life of grains and oilseeds by inhibiting microbial activity and deterioration

5 Chemical Free Approach

Ozone fumigation is an ecofriendly alternative to chemical pesticides reducing environmental impact and health concerns

6 Improved Nutrient Retention

Ozone's oxidative properties aid in preserving the nutritional content of grains and oilseeds ensuring higher quality for end consumers

Commercial Benefits Adopting ozone technology for grain and oilseed storage yields numerous commercial advantages

1 Quality Assurance

Ozone treatment preserves the quality and integrity of stored products enhancing customer satisfaction

2 Reduced Losses

By preventing spoilage pests and mold ozone technology reduces postharvest losses and improves profitability

3 Regulatory Compliance

Ozone solutions align with evolving food safety standards ensuring compliance with stringent regulations

4 Market Differentiation

Companies adopting ozone fumigation can differentiate themselves in the market by offering premium quality grains and oilseeds

Case Study Ozone Fumigation at Army Cantonments In an effort to ensure food security and quality for personnel Army cantonments implemented ozone fumigation for grain storage

Challenge Army cantonments needed to safeguard stored grains from pests and mold while maintaining food safety standards

Solution Ozone fumigation systems were installed in storage facilities Ozone's oxidizing power effectively controlled pests eliminated mold and reduced mycotoxins

Results

Pest infestations reduced by 95 ensuring food safety for Army personnel

Mold and mycotoxin levels dropped significantly preserving grain quality

Significant cost savings were achieved by reducing losses and the need for chemical pesticides

Conclusion Ozone technology proves to be a gamechanger for the grain and oilseed industry revolutionizing storage practices and quality assurance By effectively addressing pest infestations mold growth mycotoxin contamination and more ozone technology presents a sustainable chemical free and economically viable solution The successful implementation of ozone fumigation in Army cantonments underscores its adaptability and efficacy in diverse storage environments Embracing ozone technology not only enhances product quality but also underscores a commitment to sustainable and responsible agricultural practices

Contact Us For inquiries about implementing ozone technology for grain and oilseed storage contact us today Elevate your storage practices and secure a prosperous harvest with ozone technology

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+